About polylactic acid (PLA) fiber

What is polylactic acid fiber biomass:

Polylactic full name Poly Lactic Acid (PLA), although relatively unknown, but it is entirely from natural plants on Earth can be recycled. From natural plant extracts such as cassava starch and through biological fermentation of lactic acid bacteria to form polylactic acid PLA by polymerization of lactic acid. Abandoned after its products through microbial action in the soil can be decomposed into carbon dioxide and water when burned, will not emit toxic gases, does not cause pollution, is a sustainable eco-fiber.

Today, the application of PLA products are no longer confined to the field of medical surgical sutures, etc., with the depletion of oil resources and growing environmental load, making the PLA has a wider range of market applications space, because it is from sustainable natural cycles rather than petroleum-based materials products.

PLA fiber due to its excellent properties and wide application of PLA material becomes important application direction, mainly for textiles and clothing, decorative fabrics and other aspects of personal hygiene items. PLA fiber produced in the production process can still waste recycling, and waste PLA finished compost in appropriate environmental degradation can return to nature, is an eco-friendly fiber. Due to the use of bio-based renewable resources to produce, completely biodegradable, has become a substitute for petroleum-based polymer materials worldwide attention, so the PLA fiber as the "green fiber of the 21st century."

Unlike chemical fibers to impart the fiber higher functionality and add various additives in the manufacturing process, PLA fiber as a natural raw material fibers, which material itself provides excellent features.

Rising PLA fiber has the high quality features: Biomass natural fibers, non-toxic and pollution-free, soft and light, skin-friendly, good humidity, air permeability, high elastic recovery, shape stability, anti-wrinkle, natural flame resistance, antimicrobial , UV resistance.

Melt spinningOur polylactic acid fiber, from the rich natural resources, is a fully biodegradable polymer materials, its birth, so that we no longer need to rely on limited resources such as oil to produce fibers.

Currently polylactic acid fiber production technology, mostly through granulation reheated slice spinning "two-step method." Through our unremitting efforts and innovation, the formation of the world's first "continuous polymerization melt spinning" or "step" production process, and the completion of the first strip melt spinning in 2008 polylactic acid fiber for industrial production lines.

Rising manufacturing polylactic acid fiber through the "one-step" production process, reducing the slice, cooling, packaging, transportation, drying, and then heated to melt and other intermediate steps, thus reducing the possibility of an intermediate step in the impurities or undesirable factors, protect the Rising Sun polylactic acid fiber quality and stability. Not only this, the demand for a broader market, our "one-step" manufacturing process for polylactic acid PLA and modified to enhance the functionality provides a flexible and convenient copolymer blend mode.

Our process routeLactic acid aqueous solution of high temperature dehydration → → → cleavage prepolymerized crude lactide → → → purification → fine lactide ring-opening bulk polymerization of the melt conveying → → → drawing spun filament winding → FDY

We use a polylactic acid fiber "melt spinning" technology to produce, starting from an aqueous solution of lactic acid, after lactide to polylactic acid melt and fibers, continuous and uninterrupted complete.

(1) starting from an aqueous solution of lactic acid, lactide monomers:(2) ring-opening polymerization of lactide obtained polylactide, i.e. polylactic acid:

(3) a polylactic acid melt spinning.

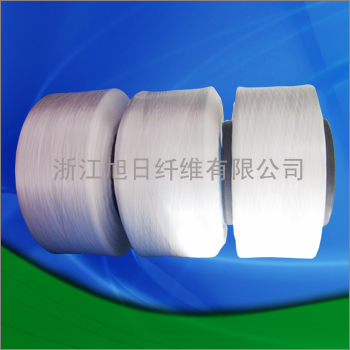

Corn fiber FDY

At present, the use of a variety of fiber products:

We contacted the fiber products in which the filaments (drawn yarn) as the basis for the largest fiber product types, are used only in China has reached 10 million tons a year on. As we are most familiar with polyester filament chemical fiber, high production efficiency, product development and flexible. And can be directly used for weaving or knitting, so widely used in textiles and clothing, decorative and industrial fields. But polyester, nylon and other chemical fiber is not renewable fibers, due to their petroleum-based raw materials are made of, the face of the growing environmental impact, renewable fiber has become an inevitable trend.

Corn fiber filament (FDY) is polylactic acid PLA renewable biomass fiber, manufacturing raw materials from the rich natural resources other than oil, and eventually return to nature. Zero pollution, renewable, in line with the call of environmental protection, energy saving! Rising corn fiber filament yarn (FDY) compared to petroleum-based filament made of a polymer material has the same broad application!

Rising corn fiber filament yarn (FDY) in addition to being non-toxic and pollution-free natural fiber raw materials, but also has a soft smooth, high strength, moisture permeability, skin-friendly, good humidity and high elastic recovery rate, stable shape, wrinkle , natural flame resistance, anti-bacterial, UV resistance and other advantages. Thus the sun corn fiber filament (FDY) is particularly suitable for underwear, apparel fabrics, home textiles, upholstery and other fields. PLA fabric characteristics to provide a good hydrophilic, flexible, can be dyed, antimicrobial mildew resistance, UV resistance, biocompatibility and other good qualities.

Fiber Co., Ltd. Zhejiang Rising Sun 72D / 48F, 120D / 72F corn fiber filament (FDY).